En la etapa actual de desarrollo industrial, el petróleo y el gas son los productos básicos más populares. El petróleo y los productos derivados del petróleo han penetrado en casi todas las esferas de la actividad humana, desde los combustibles para el transporte hasta los cosméticos y los medicamentos.

El gas natural es el combustible más popular en las centrales eléctricas, la industria del cemento y el vidrio, la industria de materiales de construcción, el uso doméstico, la metalurgia no ferrosa y no ferrosa, la fundición de metales, la producción de vidrio, así como la materia prima para compuestos orgánicos en síntesis y otras aplicaciones.

La mayor parte del petróleo y el gas se encuentran a grandes profundidades de 6 kilómetros o más. Se requieren pozos para obtener estos recursos y se utilizan diferentes tipos de plataformas de perforación para perforar los pozos.

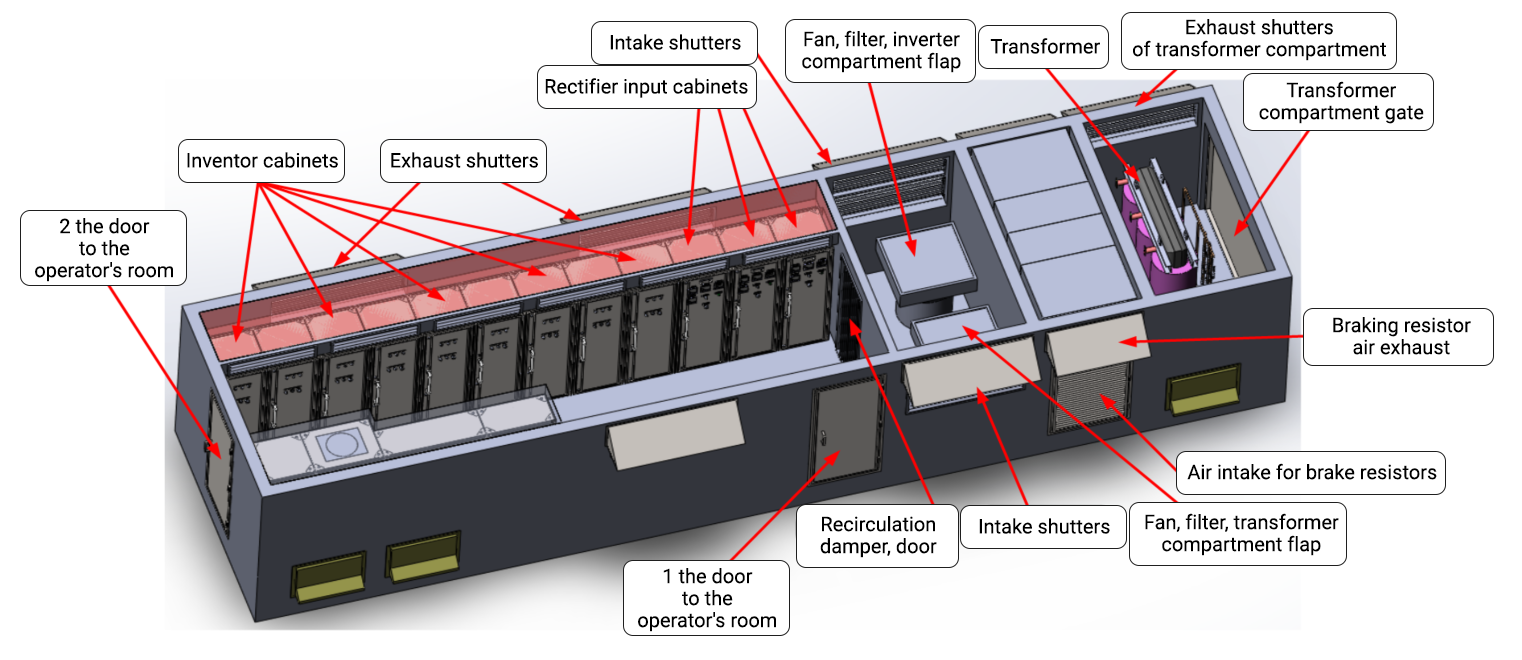

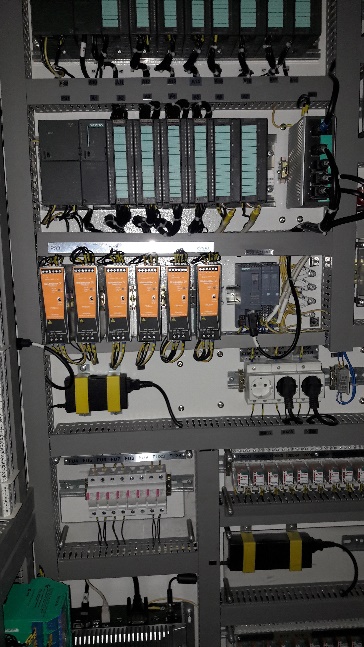

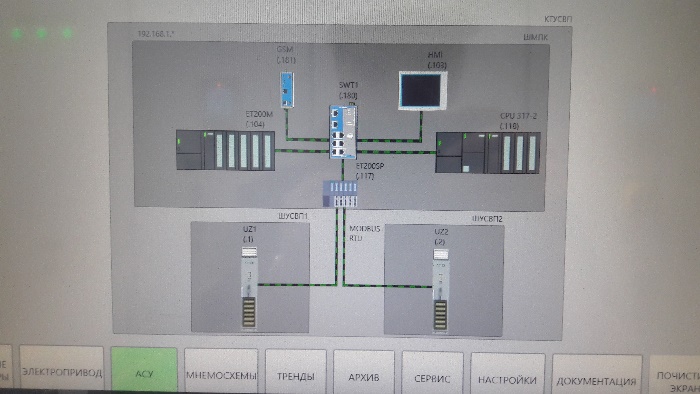

Triol Corporation ofrece una gama especial de equipos para alimentar y controlar los motores de varios tipos de equipos de perforación - línea AT24 DW (Drill Wise).

La línea DW incluye los siguientes dispositivos:

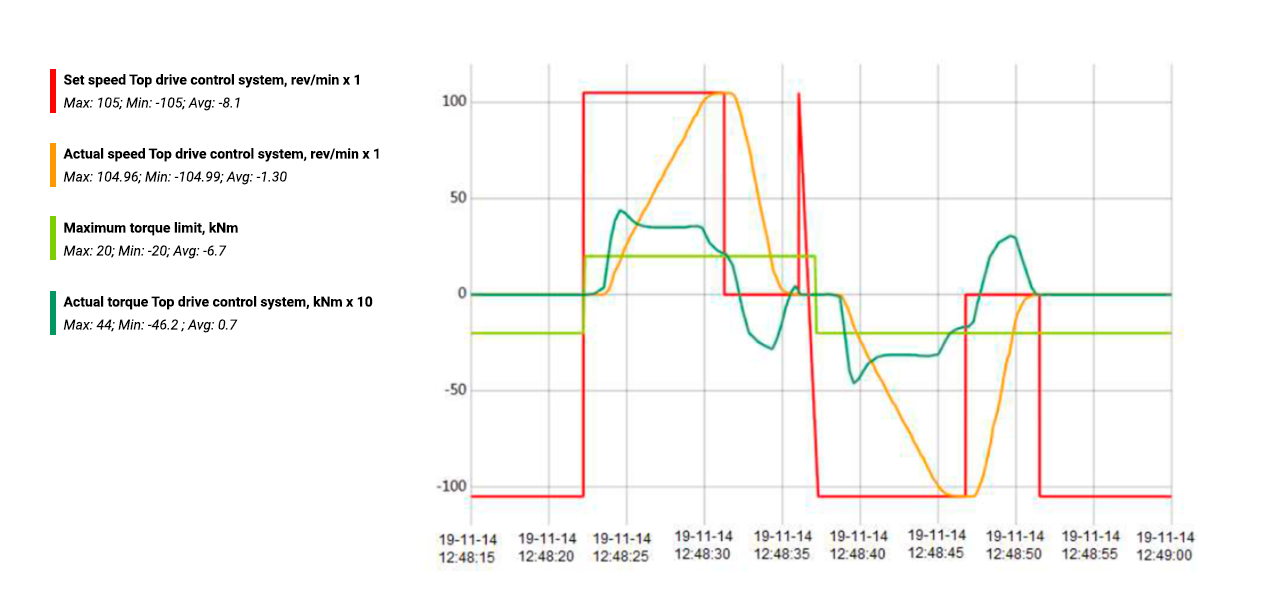

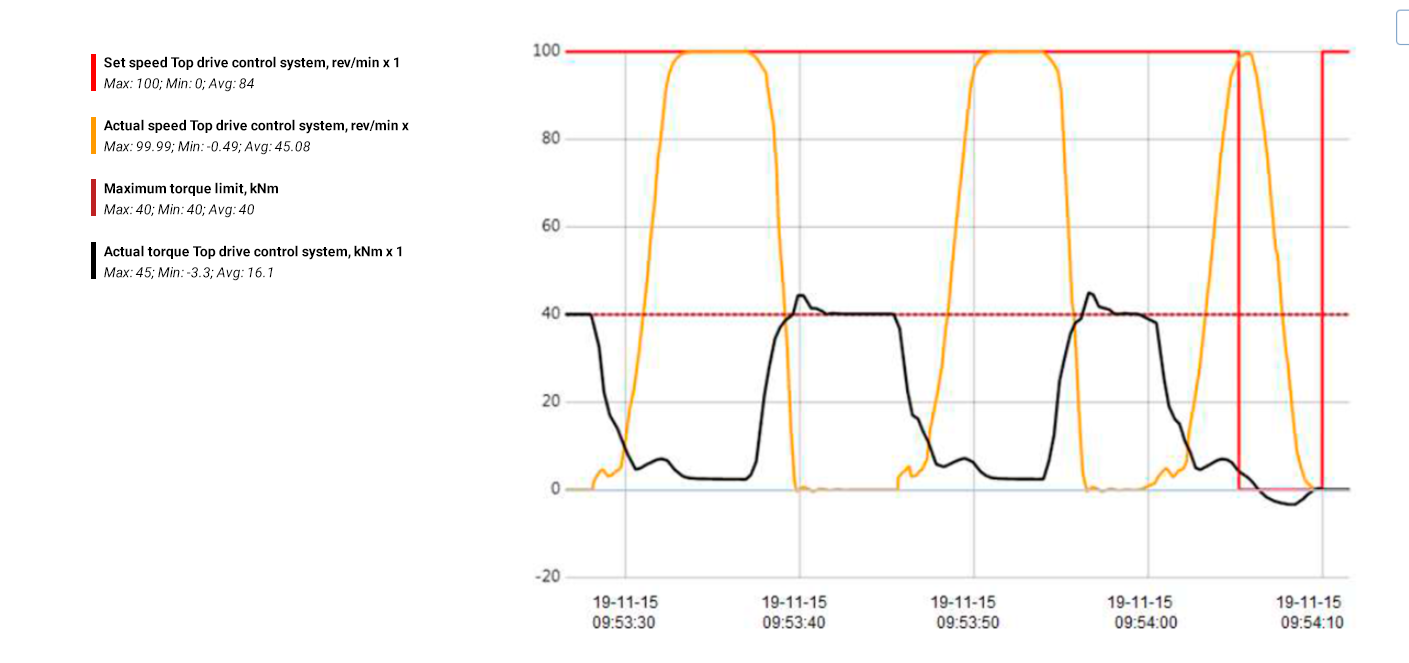

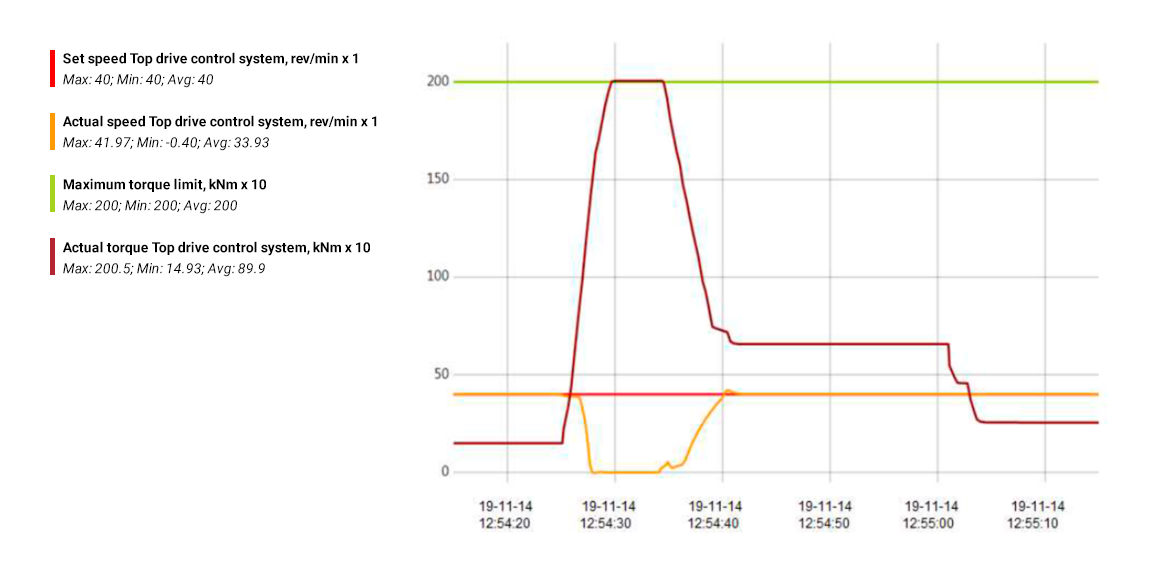

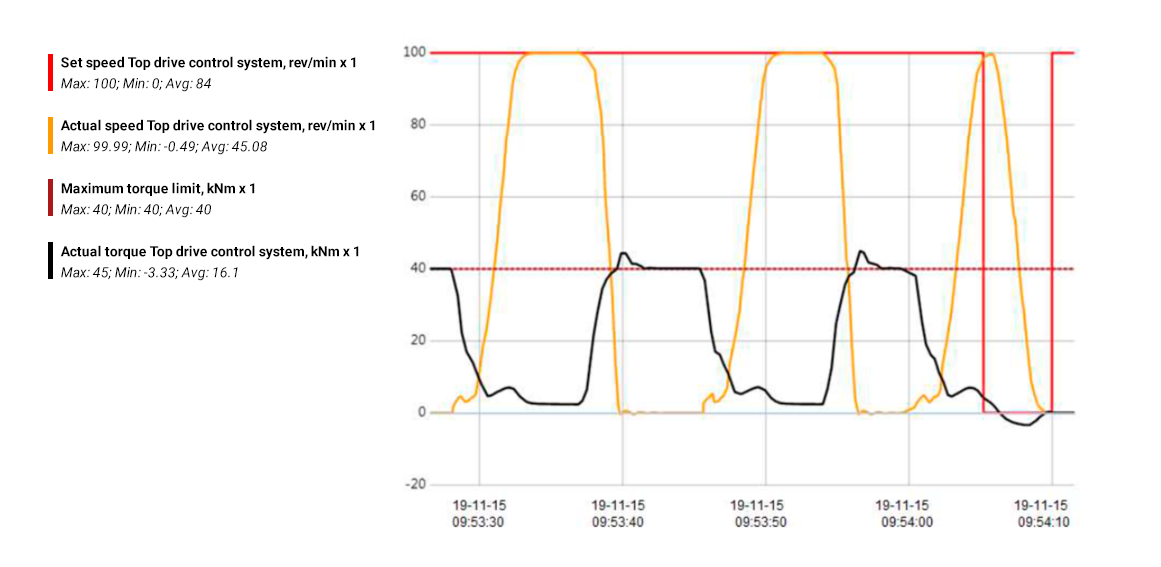

CTU TDCS –- Unidad de transistor completa para controlar el sistema de control de la transmisión superior

CTU MP - Unidad de transistor completa para controlar bombas de lodo

CTU TWU - Unidad de transistor completa para controlar la unidad de torre-cabrestante

CTU - Unidad completa de transistores para el control de todo el equipo: bombas de lodo, unidad torre-cabrestante y rotor

LVSC - Aparamenta de baja tensión y unidad de control para alimentar y controlar la maquinaria auxiliar de un equipo de perforación

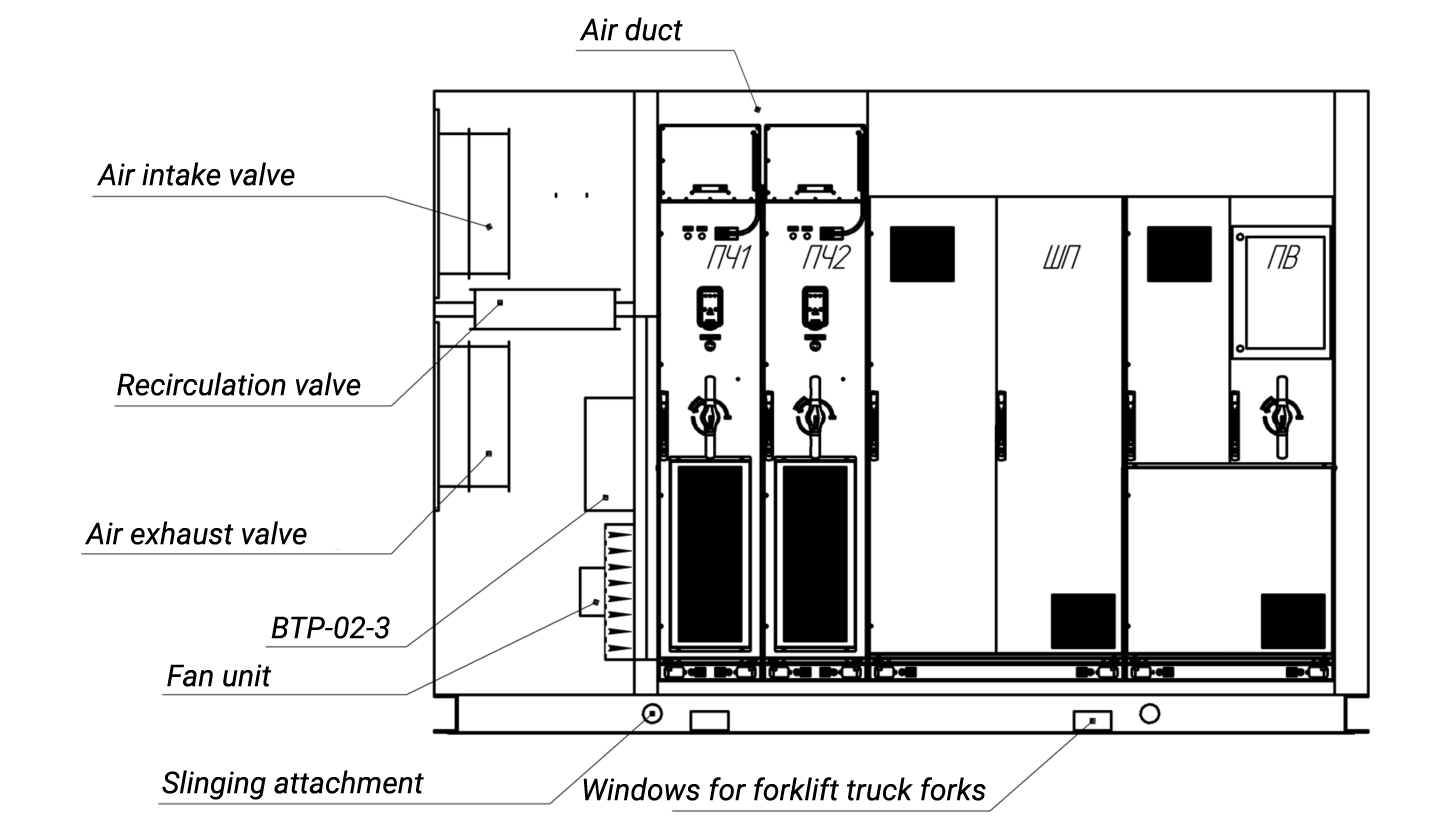

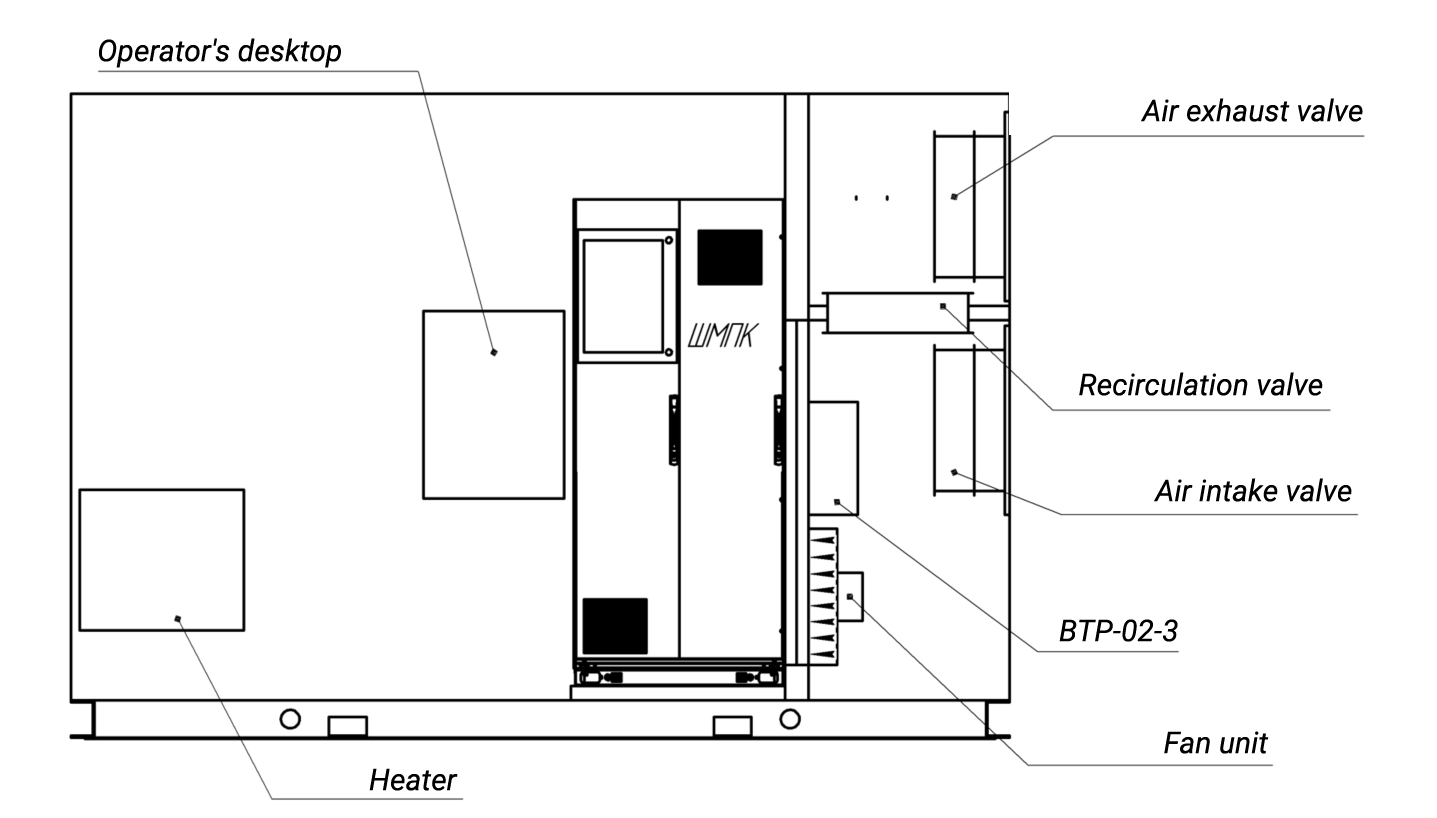

Nuestros desafíos de design:

1) Gran capacidad de montaje de equipos;

2) La mantenibilidad;

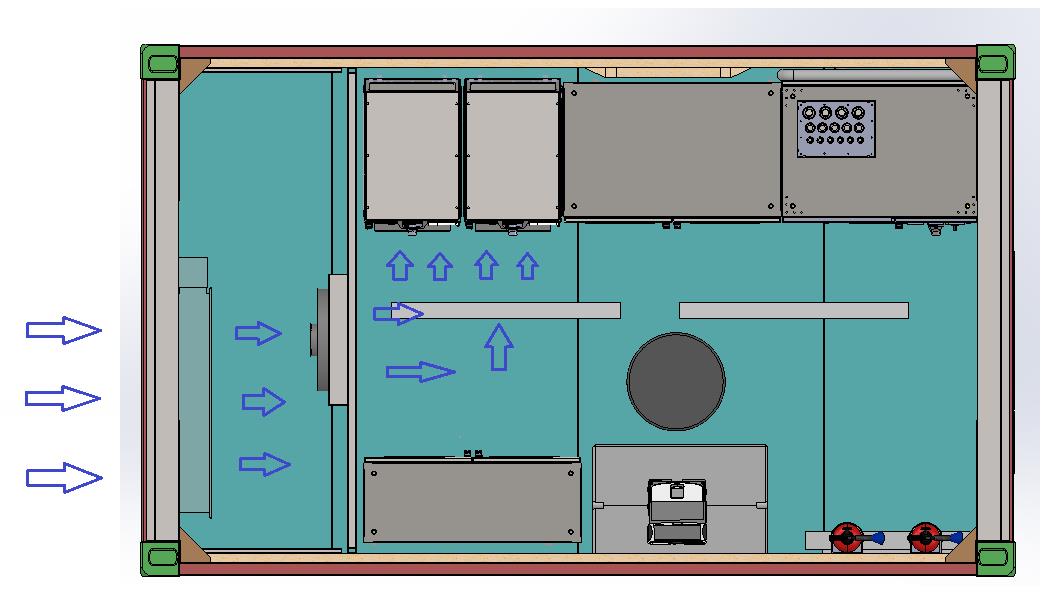

3) Las condiciones dentro del contenedor;

4) Comodidad del personal;

5) La ubicación del VDF en las cajas;

6) Un enfoque individual;

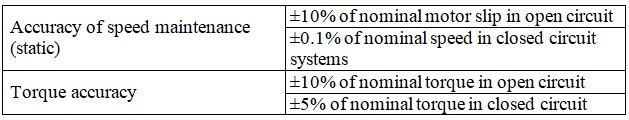

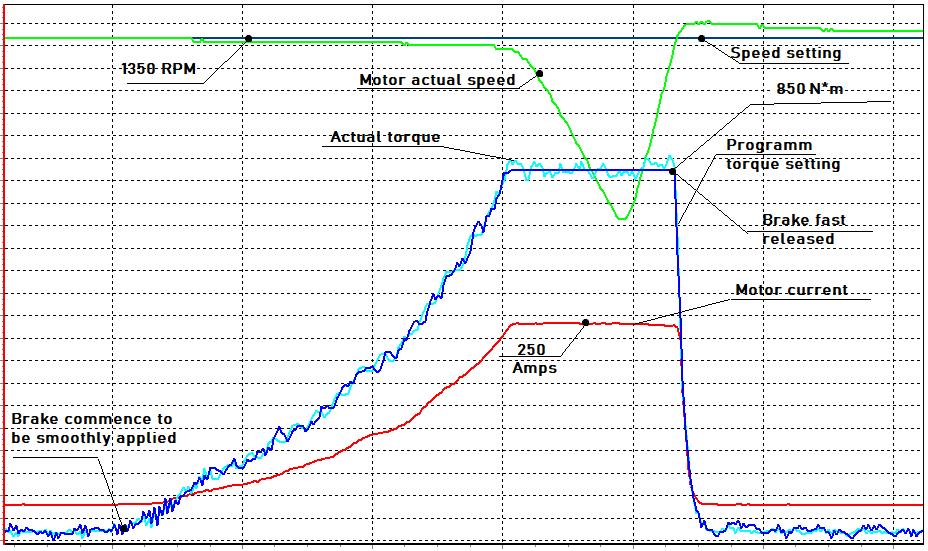

7) Control de vector;

8) Operación de motor dual con el algoritmo maestro-esclavo.