Increasing the profitability of production is an essential task to compete in today's market.

The use of modern automation means a reliable and most profitable way to increase profitability. The frequency control of electric motors is an integral part of the automation of almost any metallurgical process.

Triol Corporation sees the following main directions for increasing the profitability of rolling mills through the use of frequency control of electric motors in metallurgical production technologies:

- Automation of the rolling mill and related mechanisms to achieve the required production levels;

- Improving the quality of products by maintaining specified parameters in continuous production lines, such as rolling, hardening, casting, and cutting of metal products;

- Reduction of energy costs by controlling the speed of the executive mechanism and providing optimal torque of the executive mechanism;

- Reduction of repair and maintenance costs, which is achieved by eliminating the shock and peak loads on the mechanism.

- Reduction of defect costs due to trouble-free operation of the VFD.

Another way to improve productivity and profitability of metallurgical production is the implementation of the Triol AT24 series frequency drives with new functionality together with new AC motors to replace worn-out DC machines and automation systems of the previous generation, which were built upon their foundations.

Among the wide availability of other frequency drive manufacturers, the new functionality of the Triol AT24 series VFDs is a promising area for the modernization of metallurgical production. For example, for rolling mills, the Triol AT24 VFD has a dedicated software package, "Rolling Mill," which, in addition to the basic functionality of the VFD, contains algorithms specifically designed for use in rolling mill mechanisms that will increase productivity, reliability, and overall energy efficiency of rolling mill production.

The software package includes the following algorithms:

- Vector control

- Master-Slave

- Spindle positioning

- Bend compensation

- Shock compensation

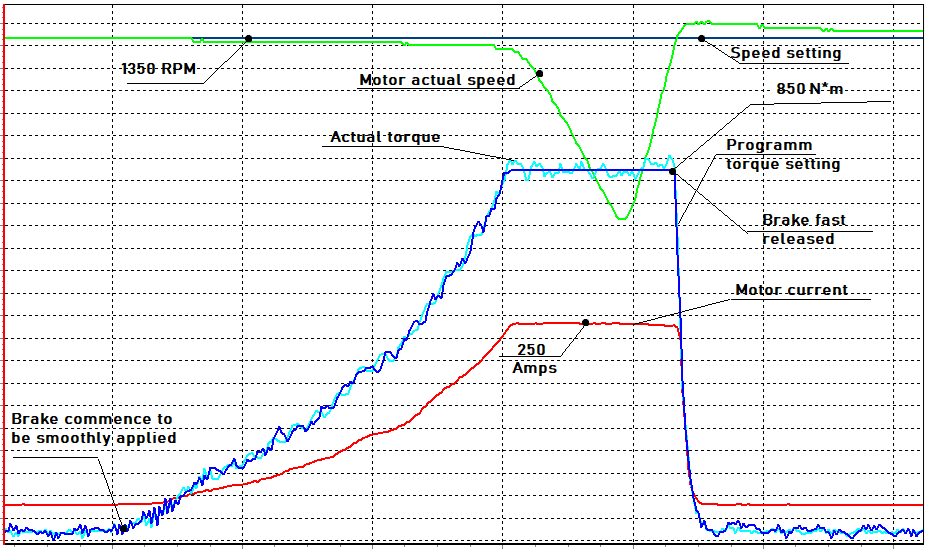

Vector control with proprietary algorithms with motor torque limitation and motor speed control in the Triol AT24 series VFD provides reliable protection against motor overloading and motor shaft torsion under critical loads.

When the value of torque produced by the motor reaches the limit value, the VFD reduces the motor speed to ensure a safe value of torque and, therefore, motor current.

Motor torque limitation:

The brake application and release at 200% torque limit setpoint without shaft block.

Precise torque and motor speed control ensures that when the torque-limit algorithm is triggered, the mill can roll at a lower speed, but without stopping the mill or breaking down due to critical load.

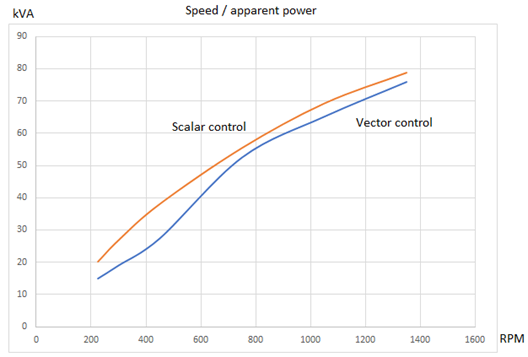

The speed-optimized vector control algorithm developed by Triol Corporation reduces the total power consumption of the motor through high-precision control and optimized motor-magnetic flux. This reduces power consumption by up to 20%. The illustration shows the result of a total power measurement at different frequencies at rated motor current.

Reduced power consumption

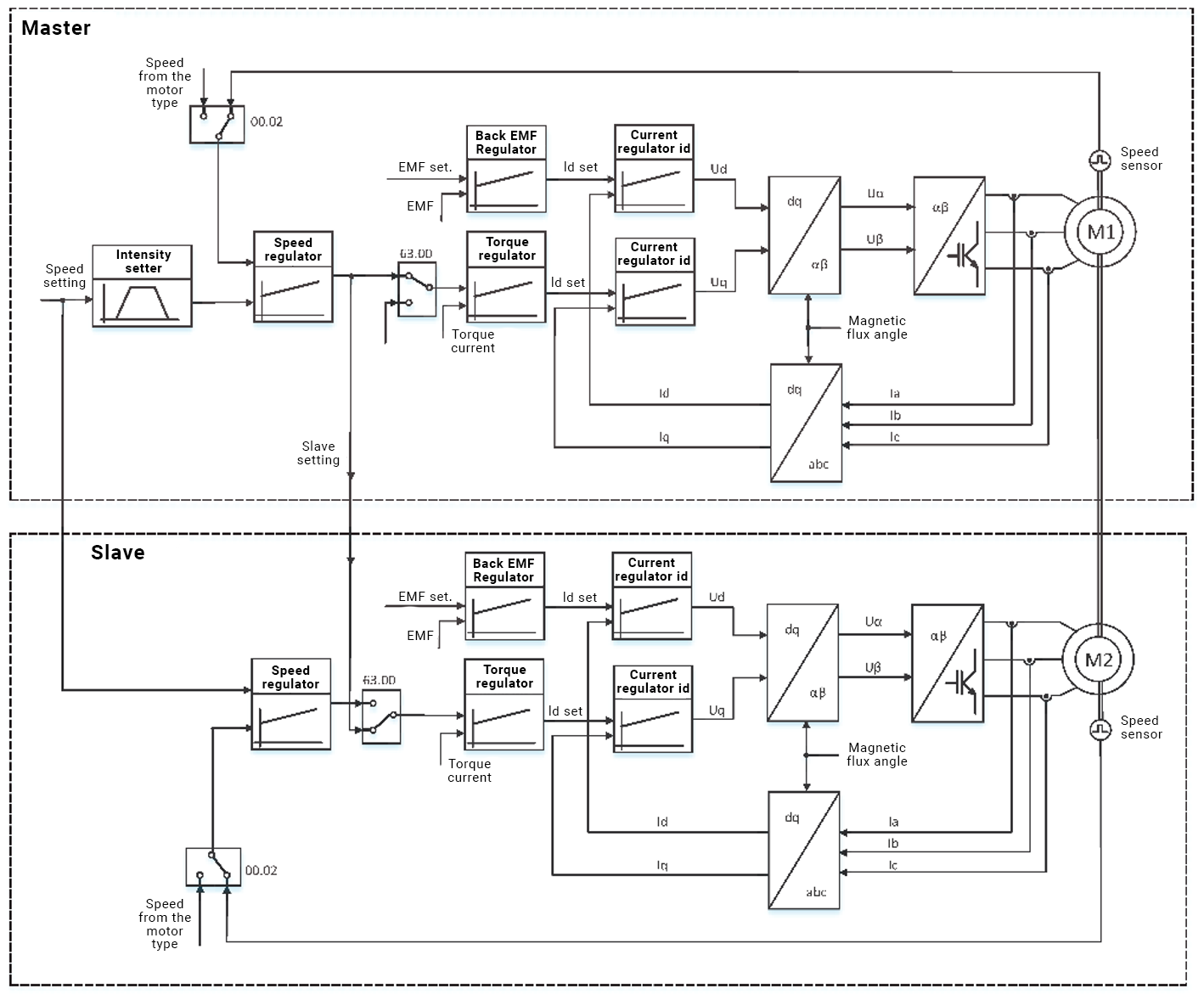

• The "Master-Slave" algorithm ensures the operation of rolling mills with several rolls in cases where the stand has a separate drive for each roll, operating in pairs (or dual drive). Dual drive means that the two drives are individually but synchronously controlled in terms of speed and load torque in order to redistribute the load in the desired ratio.

The main functions of the algorithm are:

- Controlling automatic speed or torque of the main roller drive motors according to a setpoint signal;

- Equally distributing load torque between the two drive motors;

- Avoiding a mismatch in the speed of the motors before the system is stopped due to a high voltage failure or one of the motors is overloaded. The "Master-Slave" algorithm also includes a set of interlocks for running the two drive systems of the upper and lower rolls together at the same time.

Structure diagram of the "Master/Slave" algorithm in vector control:

The master-slave algorithm included in the Rolling Mill software package of the AT24 variable frequency drive solves the following problems:

- Organizing the automation of multi-shaft drive stands;

- Distributing the load on the engine and mechanism equally, resulting in steady wear and a longer overall service interval for preventive maintenance;

- Consistently maintaining the speed of the rolls during load changes, reducing the number of rejected sheets due to different speeds of the rolls;

- Using the spindle positioning algorithm to set the spindle to the set position for roll override. Spindle positioning is only allowed when the lock is released. The lock is released by the mechanical equipment when the enable signal is received, provided that no other operating modes are active at the time. Accurate spindle positioning will reduce time and labor costs during stand maintenance and speed up production restarts on the line.

Bend compensation. Often the beginning of a sheet tends to bend downwards at high stand gaps and upwards at low stand gaps during the last passes. An important characteristic of how the speed of the rolls affects the bending of the front of the sheet is the form factor. This depends on the radius of the rolls, the thickness of the material being rolled, and the compression. The bend also depends on the ratio of the radii of the top and bottom rolls. In order to compensate for the bend at the beginning of the strip, a special control algorithm has been developed, which influences the constant component of the speed error between the top and bottom roll at the moment of pick-up. The level of compensation depends on the form factor, and the level of compensation is calculated on the basis of an adjustable compensation scheme in the control system.

The use of a bend compensation algorithm will reduce the amount of material rejected during rolling.

- Adaptive impact compensation is a function for reducing speed sag at the moment of billet gripping. Billet clamping performance is one of the most critical performance indicators of hot rolling mills.

The main features are:

- Reduced speed sag or shock sag at the moment of gripping, resulting in thickness deviations;

- The reduction of peak torsional forces in the drive chain;

- A reduction in these forces has a positive effect on the mill's mechanical equipment, reducing its wear and tear and therefore reducing mill downtime.

All Triol AT24 frequency drives are equipped with a Wi-fi module with an integrated web server, which is used as a remote control. The Wi-fi remote control allows the variable frequency drive to be set up from any device, be it a phone, tablet or laptop. The VFD menu has been developed based on numerous feedback from the Triol AT24 field and is designed to reduce the time for new users to get used to it. You can find out more about the AT24 Wi-fi remote control on our YouTube channel.

The software solutions proposed for the application of the Triol AT24 series as drives for rolling mills will improve the quality of production, reduce rejected material, reduce the possibility of machine breakdowns and reduce electricity costs, thus increasing the overall profitability of rolling mills.

Don’t miss your elegant solutions!

- Product news

- Events

- Discounts

More news

|