Oil production with sucker rod pumps (here and after referred to as SRP) is the most common way to lift oil. This is due to their simplicity, efficiency, and reliability. At least two-thirds of active production wells are operated with SRPs.

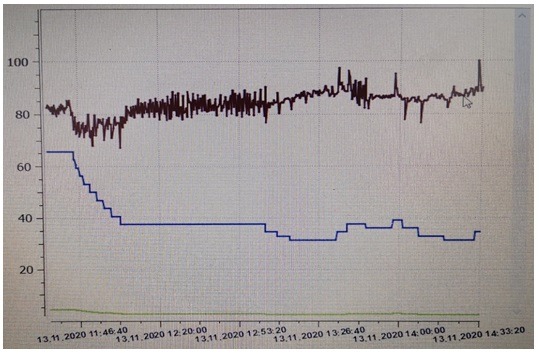

The cornerstone of oil production is to maximize production while reducing electricity costs. The installation of Triol’s variable frequency drives with downhole controllers can solve both issues.

Triol offers the user two variable frequency drive lines for controlling the SRP downhole controller:

SR line

- Hinged cabinet with IP55 degree of protection;

- Main circuit breaker;

- Variable frequency drive;

- Heating and ventilation system for open air operation;

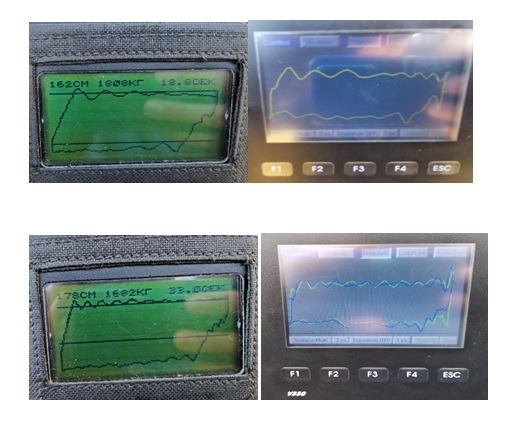

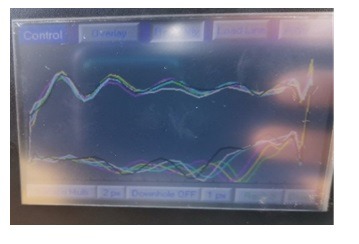

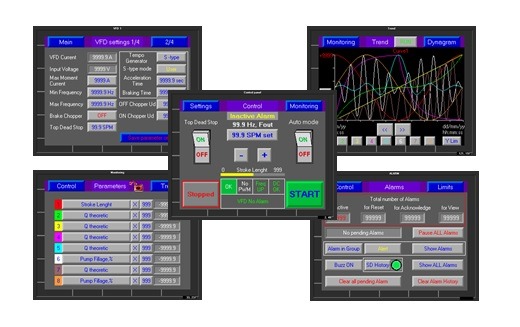

- Intelligent downhole controller with a 3.5'' or 5'' touch screen;

- GSM/GPRS modem with remote antenna and web service for remote monitoring and configuration;

- 3f + N panel outlet with circuit breaker for power supply to other devices.

RT line

- IP54 or NEMA3R rated cabinet;

- Main circuit breaker;

- Variable frequency drive;

- Heating and ventilation system for open air operation;

- Intelligent downhole controller with 3.5" or 5" touch screen;

- GSM/GPRS modem with remote antenna and web service for remote monitoring and configuration;

- 3f + N panel outlet with circuit breaker for power supply to other devices.

The following options can be optionally installed in the cabinet:

- Braking chopper and braking resistors;

- Main choke or passive filter to reduce influence of VFD on mains;

- Filter dU/dt or the sine-wave filter to protect VFD windings from peak overvoltages occurring during operation with VFD;

- Bypass circuit for switching the motor of the SRP independently of the VFD.

Our challenges when developing VFDs for SRPs:

1) Reduction of equipment cost;

2) Ease of use;

3) Increased well flow rate due to unique algorithms in the controller software.