AT27 - Compatible with all motor types! The question of compatibility of frequency drives with electric motors used in industry and utilities has not often arisen today, and yet it is one of the key issues when the end user selects a frequency drive. Let's take a look at the main reasons that can influence the choice of a particular VFD for operation with different electric motors:

-

Motor overheating;

-

The breakdown of stator winding insulation;

-

Wear of the electric motor bearing; and

-

The technical condition of the electric motor.

Motor overheating

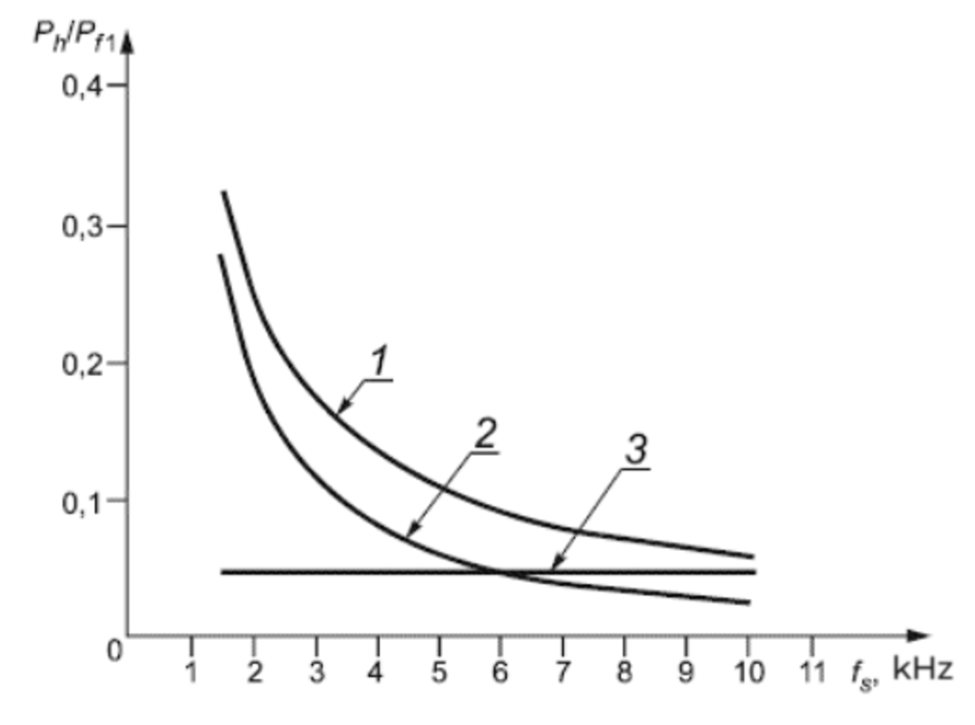

It is important to know that as the temperature of motor windings rises above the permissible values, the service life of the insulation becomes shortened rapidly. Therefore, the heat resistance of the insulation is the main requirement that determines the reliability of operation and the service life of the motor, which on average should be 15-20 years. The most commonly used motors in the industry are made with heat resistance class B and F, with allowable temperatures of active parts of the motor at 130 ° C and 155 ° C, accordingly. For harsh operating conditions, motors with heat resistance class H, with an allowable temperature of the active parts of the electric motor at 180 ° C, are produced. In general, these are motors for special purposes, designed for metallurgy, mining equipment and transport. Therefore, it is important not to create additional heating of the motor during its operation from the VFD. This is possible if the stator and rotor windings are not influenced by harmonic currents or are within the limits specified in IEC 60034-17. Higher voltage and current harmonics in an Induction motor powered by a frequency drive cause additional losses in the steel, stator, and rotor windings. For motors powered by voltage inverters, the additional losses in the steel cannot be neglected. They depend on the amplitude of the harmonic components of the phase voltages and are almost independent of the frequency (see fig. below item 3). While winding losses are strongly frequency-dependent and decrease with increasing frequency (see fig. below, item 2). The leakage inductances of these windings limit the harmonic currents determining the losses in the motor windings. Although the currents of these harmonics are small, their losses in the windings also cannot be neglected due to current displacement (surface effect and skin effect) at high frequencies. This circumstance applies to both coil and bulk windings. Rotors with a pronounced displacement effect are particularly sensitive to these losses. The dependence of steel and winding losses is shown in the figure below.

1 - total losses caused by harmonics; 2 - losses in windings; 3 - losses in steel

Numerous tests have shown that the total amount of additional losses caused by harmonics is independent of the load. It decreases with increasing switching frequency, as shown in the figure below, due to the reduction of winding losses at high switching frequencies.

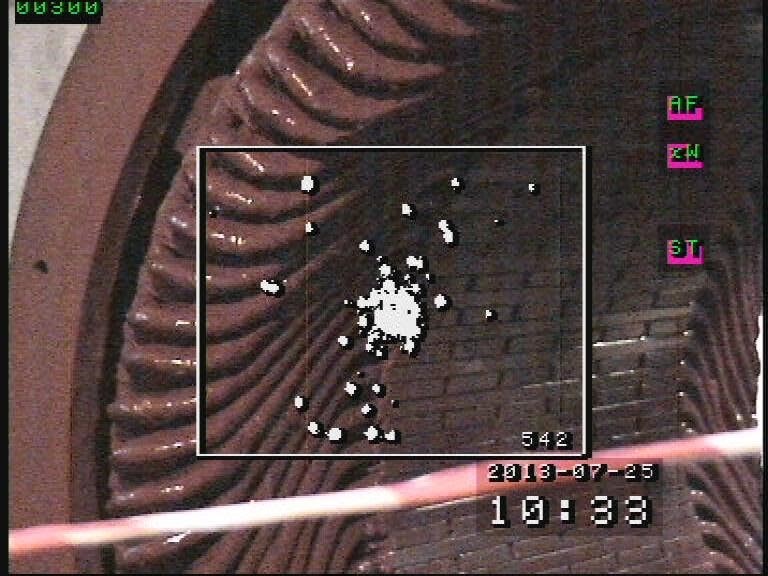

Additional heating of the active parts of the electric motor leads to the fact that not all frequency drives are able to operate with electric motors made with heating class B. This is a fairly large group of electric motors, which were originally designed for a direct or soft start without frequency control. An example of how the insulation of the old windings of an electric motor with thermal class B, which has been operated under harsh conditions, is damaged, is shown in the figure below:

Corona discharges are shown in places of stator winding damage during an ultravision examination of stator insulation of an induction electric motor.

Breakdown of stator winding insulation

One of the most dangerous effects leading to the damage of stator windings is the effect of dV/dt of the output voltage of the frequency drive. There are many myths surrounding this phenomenon due to a lack of understanding of its effect and how it affects the insulation of stator windings.

Let's consider in detail the nature of this effect, as well as the physical processes in the motor windings caused by it.

- dV/dt- is the rate of the rise of the output voltage of the frequency drive, determined by the edge of the voltage generated by the power switch of the VFD inverter, e.g., an IGBT transistor.

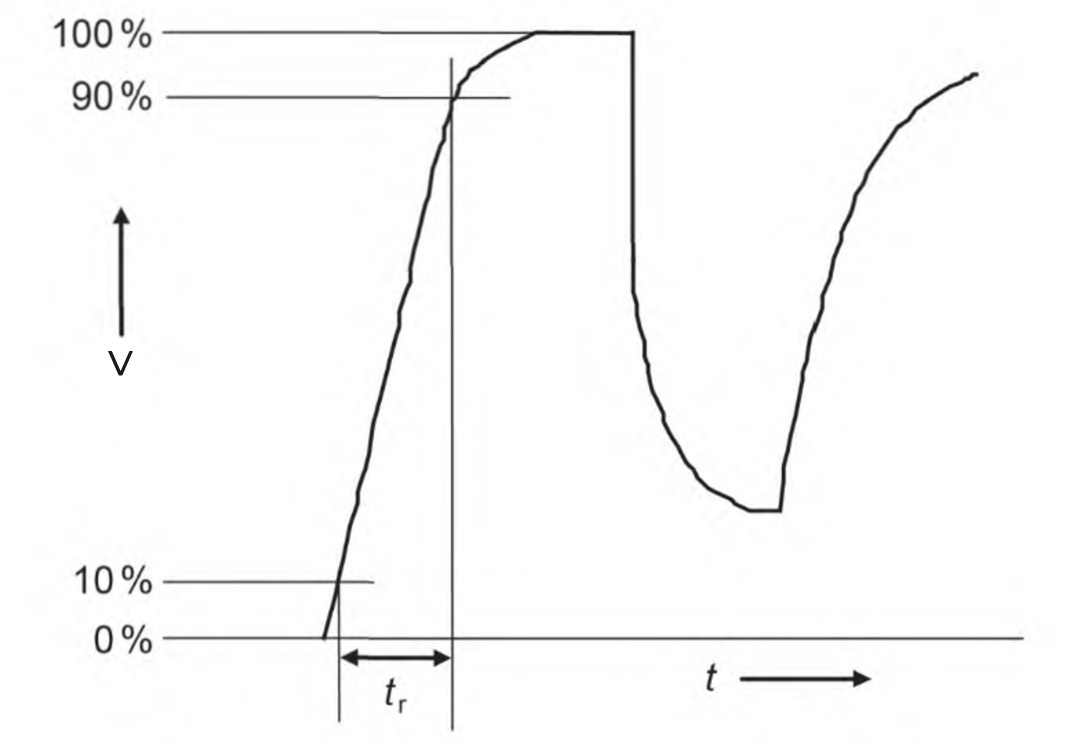

According to IEC 60034-25, dV/dt is defined as:

where

V90% - voltage level corresponding to 90% of the pulse amplitude value, V;

V10% - voltage level corresponding to 10% of the pulse amplitude value, V; and

tr – pulse voltage rise time from the 10% level to the 90% level, µs.

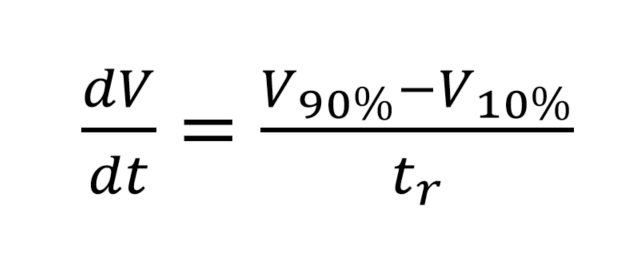

- The pulse of the generated voltage is sent to the electric motor through the connected cable line. At the motor terminals the pulse is converted into a voltage whose shape resembles a damped oscillation, whose amplitude reaches twice the amplitude of the generated VFD pulse (see IEC 60034-17, IEC 60034-25). In some cases, the increase in peak voltage on the motor terminals exceeds the allowable values for long-term operation, which leads to rapid aging and breakdown of the stator winding insulation.

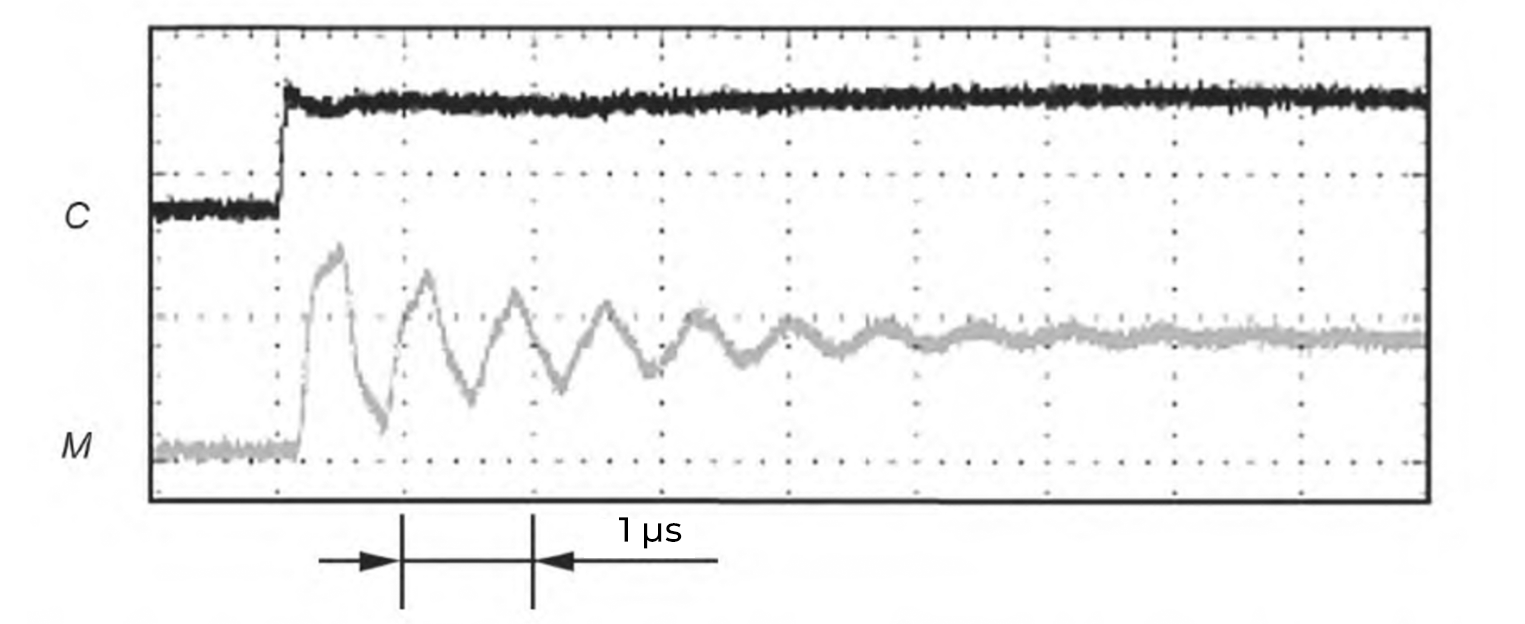

The figure below shows an equivalent diagram of the cable line between the VFD and the motor, and the response of the cable line to the applied voltage pulse.

Typical output voltage pulses in one phase of the VFD (graph C) and at the motor terminals at the end of the cable line (graph M).

- Depending on the quality and homogeneity of the impregnation, the material may contain voids (cavities) in which the process of destruction of the inter-strand insulation occurs. Deterioration of motor insulation due to voltage peaks occur by means of partial discharges. A complex effect occurs as a result of Corona. There is a relative voltage between neighboring charged conductors, which leads to an electric field. If the generated electric field is high enough (but lower than the breakdown voltage of the insulating material), the electrical strength of the air is broken. If enough energy is available, oxygen (O2) is ionized into ozone (O3). Ozone is extremely aggressive and damages the insulation. For this, the voltage on the conductors must exceed a critical threshold value, the so-called "Corona Start Voltage", i.e., the local breakdown strength in the air (in the void). The Corona Start Voltage depends on the winding design, insulation type, temperature, surface characteristics and humidity. The weakest insulation is the inter-twist insulation, especially in the area of the outermost turns (see IEC 60034-17).

Example of damage to the stator winding insulation of an induction motor.

Wear of the electric motor bearing

Accelerated wear of the bearing due to the frequency drive and motor operating together is one of the crucial criteria for selecting a frequency drive for operation with old, non-frequency-controlled motors. The essence of the problem is the presence of higher-order in-phase harmonics in the output form of the VFD voltage and the flow of currents through which the parasitic capacitance of the motor leads to the degradation of the reference bearing. IEC 60034-17 specifies that when a motor is operated from a sinusoidal mains voltage, the circular flux of the stator yoke induces an axial electromotive force (EMF) in the circuit formed by the shaft, bearings, flange and housing, as shown in the figure below.

The ring is defined as the axial EMF and parasitic current icirc

The ring flux is caused by inhomogeneities of the fair (dovetail for fair attachment, vent channels, and magnetic anisotropy of the plates). Usually the axial EMF is determined by the supply frequency and its threefold frequency caused by nonlinearity of the magnetization circuit. Experience has shown that if the axial EMF does not exceed 500 mV, there is no need for additional protective devices. Otherwise, currents pass through the bearings, which can destroy them within a short time. Bearing insulation, particularly at the rear end of the shaft, is generally sufficient to avoid currents flowing through both bearings and the mechanical parts of the drive that connect it to the load. This insulation is not necessary for motors manufactured to modern requirements and supplied with sinusoidal voltage.

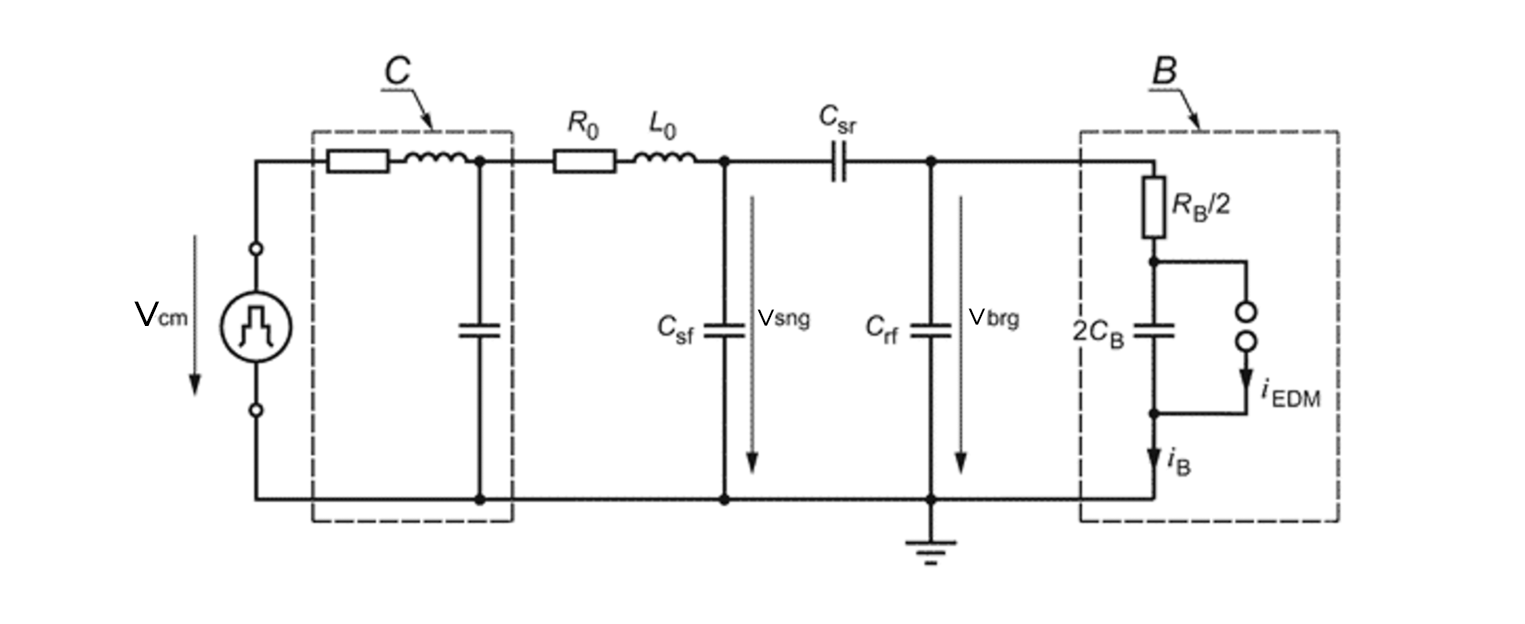

However, when supplied by a frequency drive with a voltage inverter, interference occurs, and its maximum value is within 50% of the DC-link voltage value. Since interference in all windings is in-phase, it can be considered as a zero sequence in the voltage composition. An equivalent circuit for interference is shown in the figure below.

Parasitic current circuit diagram and bearing voltage

Where:

B- bearing;

C- cable;

Csr- stator-rotor capacity;

CB- bearing capacity;

Csf- stator- Enclosure capacity;

Crf- capacity rotor - Enclosure;

IB- bearing current;

IEDM- breakdown current;

L0- leakage inductance;

RB- bearing resistance;

R0- winding resistance;

Vsng- neutral stator- earth voltage;

Vbrg- bearing voltage;

Vcm- interference voltage.

When powering from an inverter as opposed to a mains supply with sinusoidal voltage, capacitive components of resistances play a large role at high frequencies. The amplitude of the interference depends on the resistance (mainly the reactive component) of the circuit through which it flows. This circuit is shorted at the zero point of the inverter. In general, parasitic currents flow through the motor bearings in three circuits. The practice of operating properly earthed drives with frequency drivers shows the following.

In motors with a shaft height of up to 280 mm, experience has shown that bearings rarely fail due to the inverter. Nevertheless, it can be argued that dielectric wear is highly dependent on the control method and switching frequency of the inverter. The use of inverters with switching frequencies above 10 kHz and voltages above 499 V requires attention to bearing isolation.

The effect of bearing wear can be eliminated by replacing it with an insulated bearing, but this is an additional cost that not all VFD users are willing to accept.

Technical condition of the electric motor

The technical condition of the motor largely determines whether it can work together with a frequency drive. This includes:

- Operation with a reduced thermal class;

- Operation with old weakened insulation;

- Operating with uninsulated bearings;

- Rapid passage of resonant frequencies.

This is a list of the most common problems of electric motors with poor technical conditions, which the AT27 series VFD copes with perfectly.

How does TRIOL solve this problem?

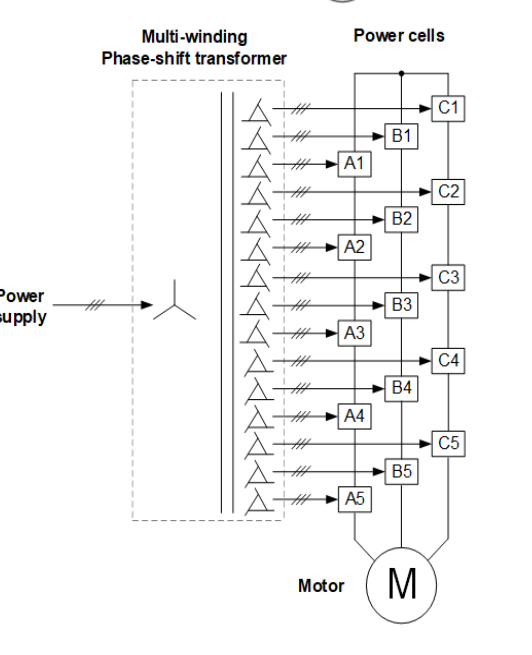

To solve the above-mentioned problems associated with the use of a frequency drive together with an electric motor, the TRIOL Corporation offers medium voltage frequency drives of the Triol AT27 series. They are built according to a multilevel topology using an input power phase-shifting transformer, the scheme of which is shown below:

Functional diagram of AT27 series frequency converter with 6 kV output operating voltage.

Such an architecture of the frequency converter allows the motor to form symmetrical quasi-sinusoidal output voltages with THDU ≤ 5%

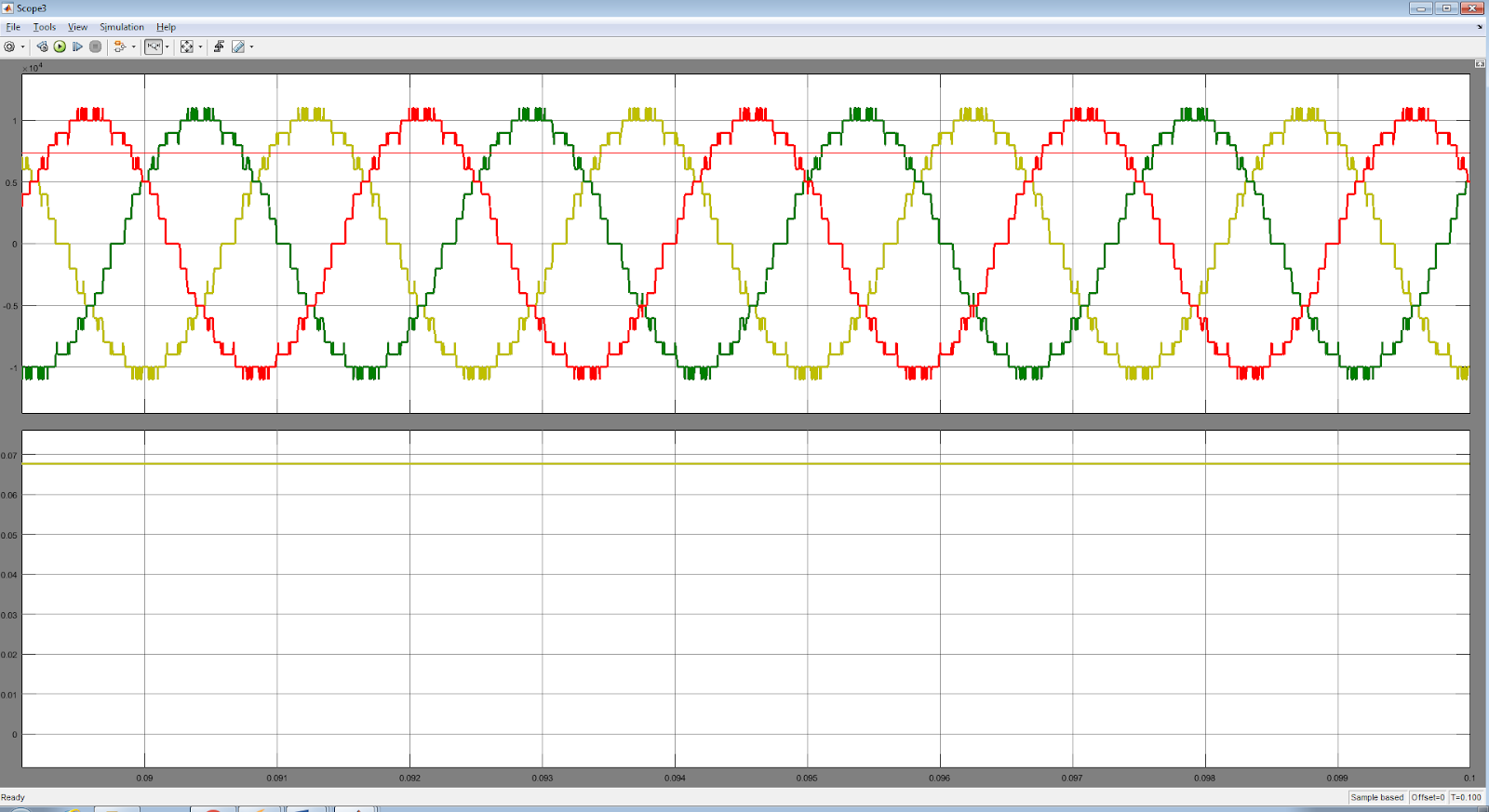

Diagram of the quasi-sinusoidal output voltages of the AT27 frequency converter. PWM frequency in voltage form is 3...10 kHz depending on the number of cells in phase.

A specially developed algorithm of adding output voltages of each power cell to the total VFD output voltage allows TRIOL Corporation to reduce the level of dV/dt = 40...50 V/µs.

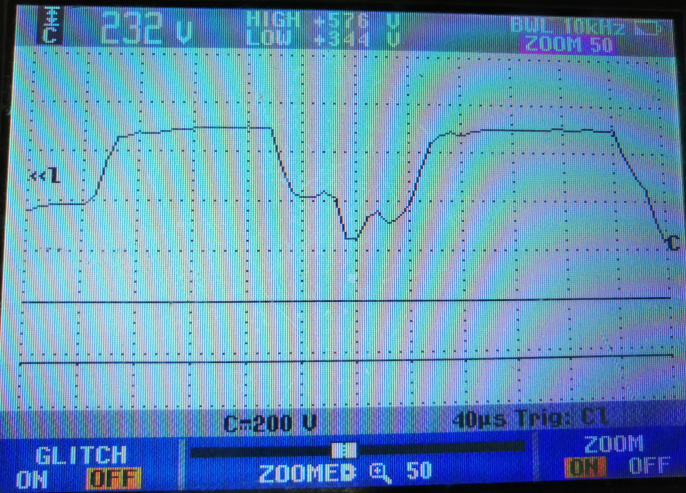

Oscillogram of the step component in the form of the AT27 VFD output voltage with dV/dt = 40 V/µs. The optional sine filter enables sinusoidal output voltages with THDU ≤ 2%, which removes any restrictions on the length of the cable line and the condition of the insulation of electric motors.

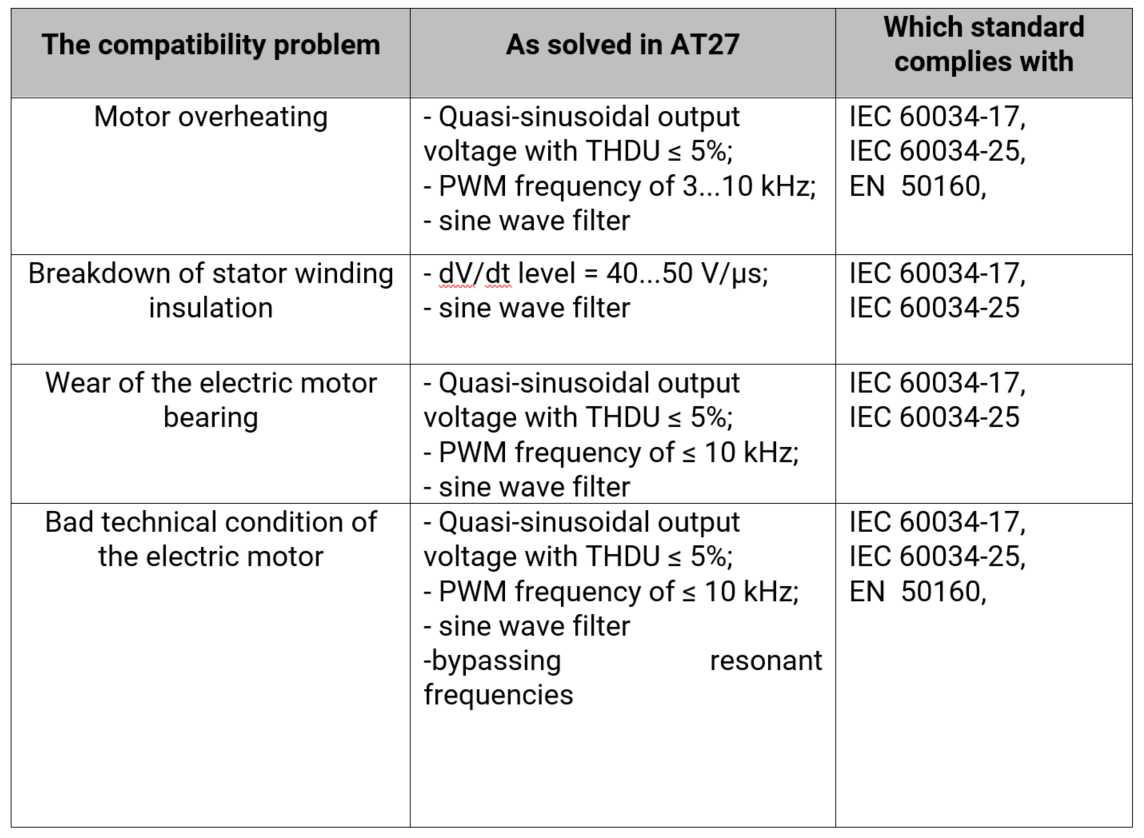

Review a summarization of how the above solutions allow the application of the Triol AT27 with any type of motor:

Conclusion

Understanding the physical processes that occur in electric motors at all life cycles and experience in studying the practices of operating users of operated electric motors has allowed TRIOL Corporation to develop a set of technical solutions that enables one to exclude any restrictions on the use of AT27 frequency drive with the existing number of general industrial and special electric motors. This has made the TRIOL AT27 VFD a valuable tool for the implementation of a wide range of tasks in industrial and municipal sectors.

Não perca suas soluções elegantes!

- Novidades do produto

- Eventos

- Descontos

Mais notícias

|